Heinrich’s domino model of accident causation

Herbert W.

Heinrich was a pioneering occupational safety researcher, whose 1931

publication Industrial Accident Prevention: A Scientific

Approach [Heinrich 1931]

was based on the analysis of large amounts of accident data collected by

his employer, a large insurance company. This work, which continued for

more than thirty years, identified causal factors of industrial

accidents including “unsafe acts of people” and “unsafe mechanical or

physical conditions”.Unfortunately, H. W. Heinrich’s books are out of print,

and quite difficult to find. Copyright on the 1931 edition of his book

Industrial Accident Prevention is due to expire in 2026 (28 + 67 years from

the date of publication, according to this author’s understanding of

article 304 of US copyright law). The 1941 edition of the book is available

online at archive.org, thanks to the Digital Library of India.

Heinrich is most famous for originating the concept of the “safety pyramid”. He also

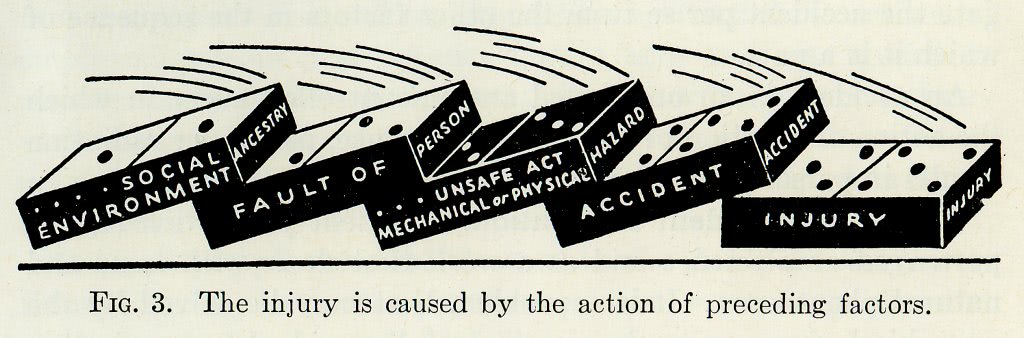

developed the “five domino model” of accident causation, a

sequential accident model which has been influential in

the development of occupational safety thinking. His “domino theory”

represents an accident sequence as a causal chain of events, represented

as dominos that topple in a chain reaction. The fall of the first domino

leads to the fall of the second, followed by the third, etc.,A similar analogy was in use in geopolitical theory

during the Cold War, speculating that if one country “fell” to

communism, then surrounding countries might quickly follow. This domino

theory was used by the US administration to justify the need for

American intervention in various parts of the world.

as illustrated below.

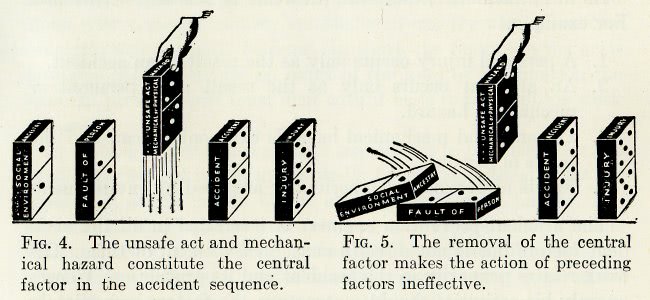

Heinrich saw the occurrence of a “preventable injury” as the culmination of a series of events that form a sequence, similar to a row of dominos placed so that the toppling of a first domino knocks down the next, which makes the third fall down, and so on until the entire row is toppled. If this series is interrupted by the elimination of even one of the several factors that comprise it, the injury will not occur, as illustrated in the figure below:

In the first version of this model, published in 1931, the five factors identified were:

domino 1: ancestry and the worker’s social environment, which impact the worker’s skills, beliefs and “traits of character”,Heinrich wrote that “Recklessness, stubbornness, avariciousness, and other undesirable traits of character may be passed along through inheritance”. This kind of belief is not very different from that held by supporters of eugenics.

and thus the way in which they perform tasksdomino 2: the worker’s carelessness or personal faults, which lead them to pay insufficient attention to the task (see box about “accident-proneness” theory)

domino 3: an unsafe act or a mechanical/physical hazard, such as a worker error (standing under suspended loads, starting machinery without warning…) or a technical equipment failure or insufficiently protected machinery

domino 4: the accident

domino 5: injuries or loss, the consequences of the accident

“Accident-proneness” theory

During the period 1920–1960, a number of industrial psychologists put forward a theory that certain workers are more “accident-prone” than others (they are more likely than others to sustain accidents, even though exposed to equal risk) [Burnham 2008]. Some people working in high-hazard industries still hold this belief. However, research since the 1960s shows that this theory has little validity. Some population categories do tend to have more accidents than others (for instance, young male drivers tend to have more car accidents than older — more experienced — drivers), but these factors concern a category of people (age, level of experience, level of education, for example) rather than a specific individual. Organizational and workplace factors have a greater impact on the occurrence of accidents than factors related to the individual. Finally, any theory concerning accidents that leads to the allocation of blame on individuals has many negative side effects for safety, such as encouraging defensive reactions by individuals that strongly reduce the reporting and sharing of safety information. For these reasons, “accident-proneness” theory is not a useful concept for safety management.

Over time, the idea of attributing workplace behaviour to ancestry and to ingrained personal faults was found to be inappropriate, and more recent versions of the model replace the labelling of the first two dominos by aspects related to planning, work organization and leadership, or more generally management’s control of organizational factors of safety.

This theory of accident causation was later further developed by Frank Bird, who improved the description of managerial “dominos”, and who generalized the last “accident” domino to cover any loss (lost production, damage to equipment or other assets, and not only injuries).

Interpretation

This linear accident model is simple and easy to understand. Compared with the very simplistic analyses that were common at the time (“accident caused by worker error”), it helped managers to think about and identify underlying causal factors that could contribute to accidents. Its promise of allowing the interruption of the accident sequence by acting on underlying causal factors (“pulling out a domino”) helps to convince people to adopt the corrective actions suggested by the accident investigation.

However, the model can contribute to a focus on the search for culprits or people to blame in the accident sequence, rather than on a detailed understanding of all the systemic factors that may have contributed to the accident. It encourages an interpretation of workplace safety in which workers are seen as generators of accidents, rather than as people who do their best to run imperfect systems as well as possible given all the competing demands.

Criticism

The domino model is widely seen today as being too

simplistic to be a useful tool to help understand the causal

factors of accidents:For an overview of models of causation used in safety

management, see for example the chapter Models

of Causation: Safety in the OHS Body of Knowledge published by the

Safety Institute of Australia.

It leads to an excessively simple view of the contribution of human performance to accidents, and to a focus on training and procedural compliance (including “behaviour-based safety” programmes), rather than effort to improve system design, workload and incentives.

It adopts a linear and mechanical model of causality, which is inappropriate in complex systems where accidents are generally caused by many interacting, partially competing and unpredictable factors. (“Complex systems fail in complex ways” is a useful tagline.)

References

Burnham, John C. 2008. The syndrome of accident proneness (Unfallneigung): Why psychiatrists did not adopt and medicalize it. History of Psychiatry 19(3):251–274. [Sci-Hub 🔑].

Heinrich, Herbert William. 1931. Industrial accident prevention: A scientific approach. New York. McGraw-Hill.

Published:

Last updated: